Flocculators are an integral part of gas refining complexes in order to separate the liquid phase from the well outlet gas phase and send the pure gas to the refining process. Depending on the characteristics of the gas reservoir being extracted, suspended materials accompanying the gas are separated from them during the separation of the gas phases and precipitate in the lower part of the flocculator tubes. In other words, the three phases of gas entering the refinery (gas, liquid and solid) are separated from each other. The gas phase is collected in the upper part and the liquid phase is collected in the lower part. However, suspended particles or sediments gradually fill the pipe wall and reduce the cross-sectional area of the flocculator tube and its efficiency, as well as other damages to the pipe wall to the point of blocking the pipe.

Currently, the method of unclogging gas flocculators is carried out by replacing (cutting the pipe and replacing it with a new pipe), and in general, inspection and collection of information about the condition inside the pipe, as well as maintenance operations of finger flocculators, are not carried out and, if necessary, are carried out from the outside.

But the knowledge-based company of Mechanized Exploration of Fanavar has for the first time offered a new solution that allows the country’s gas industry to take a step forward in improving the safety level of its facilities by performing periodic descaling operations and regular inspections before the blockage of floc traps occurs. On the other hand, it is possible to remove the blockage and descaling even after the blockage occurs.

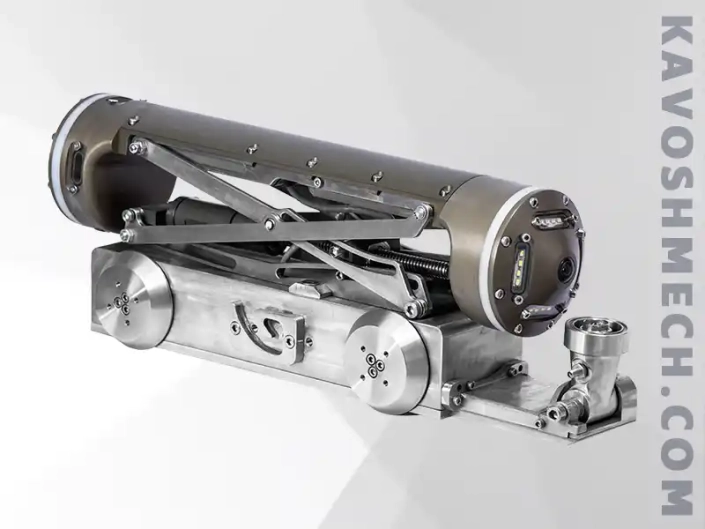

The Mechanized Exploration of Fanavar Company, relying on years of extensive washing, dredging and inspection operations in the industry and the manufacture of industrial waterjet equipment using high-pressure water jets and instantaneous discharge of high-pressure gas, achieves this important goal.

ربات تعمیرکار(CutterBot)

ربات تعمیرکار(CutterBot)