Kavash Mechanized Technology, as the first company to produce visual inspection robots for sewage networks in the country, has offered products that comply with international standards to the country’s industry under the SewBot brand. These robots have been designed and produced in various models since 2005 with the patent registration of the first model, and to date, nearly 10 models have been produced and offered to government and private customers based on practical experience in inspecting thousands of kilometers of sewage networks in the country. This family is currently known as the most reputable robot brand in the water and sewage inspection industry, which is completely competitive compared to similar products in the world, and relying on the knowledge and experience gained from the design, manufacture, and applications of previous models of sewage network line inspection robots, it is considered a product that complies with inspection standards and meets the needs of the country’s sewage industry.

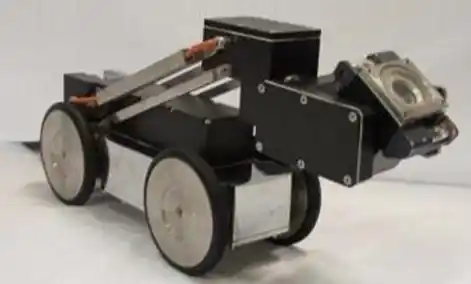

SewBot I

The first model of this robot, which is also considered the first robot made in Iran, was designed and manufactured with the Kavash 1 software to guide and record information on videometric film, a large electric cable reel with a cable organizer and a large console for installation on a van. This model had a lift to place the camera in the center of the pipe without the need to change the wheel.

The features of this robot are:

• Waterproof robotic platform with IP68 protection level

• Equipped with a two-degree-of-freedom Pan-Tilt camera

• Capable of passing through pipes with different diameters (at least 200 mm)

• Equipped with an electric camera height adjustment lift

• Equipped with an independent control system and steering handle

• Equipped with a pipe slope measurement system

• Equipped with a halogen lighting system

• Equipped with an electric cable reel and automatic cable sorter

• Capable of connecting to Kavash software

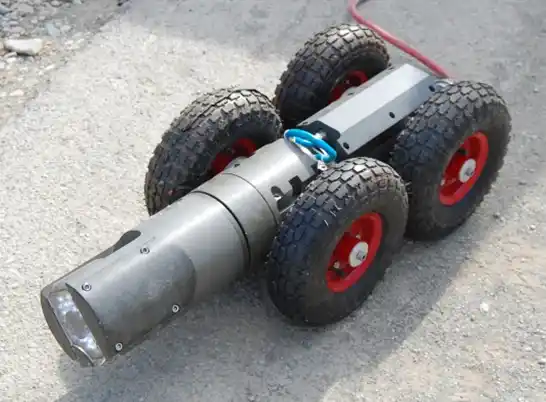

SewBot II

The second model of SewBot robots had a more beautiful and efficient body design, improved lighting by replacing LED light, and provided proper performance for videometry with an optimized and more suitable design of the robot head, which is the location of the PTZ camera. Other features of this model include:

• Waterproof robotic platform with IP68 protection degree

• Equipped with a two-degree-of-freedom Pan-Tilt camera

• Ability to pass through pipes with different diameters (at least 200 mm)

• Ability to manually adjust the camera height

• Equipped with an independent control system and steering handle

• Equipped with a pipe slope measurement system

• Equipped with a laser system for drawing instant pipe profiles

• Equipped with an LED lighting system

• Equipped with an electric cable reel and automatic cable sorter

• Ability to connect to Kavuz software

SewBot III

In the design of the third model, an attempt was made to address the shortcomings of the previous models. In the design and production of this model, based on the experiences of videometry implementation by the company’s contractor teams using the first and second generation of inspection cameras, an attempt was made to address the weaknesses of the robot in the proper implementation of videometry and the requirements and requests of the country’s wastewater experts and consulting engineers. One of the most important features of this model, which was also observed in subsequent models, was anti-overturning. The design of the robot and software was such that the robot could continue its mission even if it overturned. Improving the quality of the camera, strengthening the camera’s pan motor to remove obstacles in the way of the pipe, and adding a photogrammetry module were other features of this model.

Some of the features of Sewbot III are as follows:

Waterproof robotic platform with IP68 protection, explosion-proof and anti-erosion

Symmetrical platform that can still move and exit the pipe if it is overturned

Able to separate the camera module (modular design)

Ability to pass through pipes with different diameters (at least 200 mm)

With a color inspection camera with zoom (10x) and high resolution (600 TV lines) and controllable by software

Ability to move the camera in two directions: Pan (unlimited) and Tilt (±120)

With a powerful camera drive motor in the Pan direction (suitable for exploited lines)

Equipped with an independent control system and steering handle

Equipped with a pipe slope measurement system, a laser measurement system for two pipe expansions and a laser measurement system for the distance between joints

Equipped with 8 adjustable optical elements based on LED technology

With an electric cable reel and automatic cable sorter

Capability Connection to advanced exploration inspection software

SewBot IV

The SewBot model 4, with a slight difference from the previous model, but with a lighter and more efficient design of the cable reel and console, provided more suitable conditions for providing videometry services.

SewBot V

For the first time, Kavash was able to create a way to survey and inspect lines with a diameter of 150 mm by designing the SewBot V. This delicate robot, with its lift, allowed the camera to be centered without changing wheels. Adding a laser profiler alongside the photogrammetry module doubled the accuracy in calculating the pipe expansion. Increased inclinometer accuracy and a beautiful design were other features of the SewBot V.

The capabilities of this robot include:

Ability to pass through pipes with different diameters from a minimum diameter of 150 mm

Adjustment of the camera lens height by automatic lift

With laser ring technology to measure the expansion without stopping the robot

All-steel and waterproof robotic platform with IP68 and explosion-proof protection

Ability to separate the camera module (modular design)

With a high-resolution color inspection camera and controllable zoom, focus and iris

Ability to move the camera in two directions: Pan (unlimited) and Tilt (± 120)

With an upgraded electronic system with the ability to instantly measure the expansion with a laser profiler tool and draw a diagram

Equipped with an upgraded slope measurement system

Equipped with adjustable optical elements based on LED technology

Automatic, modular, lightweight and synchronized cable collection system with robot movement

Ability to collect at least 300 meters of special inspection cable (polyurethane coating and anti-erosion)

With a control system and steering handle Separate

Equipped with robot control keys and knobs, cable retractor, etc.

Equipped with power protector

Equipped with protected power and signal converters

Upgraded electronic system with the ability to instantly measure the double width with laser profiler tool and photogrammetry technology

Equipped with an upgraded slope measurement system for precise data filtering

Ability to connect to advanced and specialized Kavuz Inspection software with Persian menus

Advanced and specialized Kavuz Inspection 3 software with Persian menus

Ability to measure all defects inside the pipe, including the distance between joints and linear and surface damage using photogrammetry

SewBot VI

The design of this model, while maintaining the positive points of the SewBot V robot, attempted to reduce the weakness of the weak power transmission of the above robot, which led to the design of a more powerful robotic platform that is capable of inspecting networks with a minimum diameter of 200 mm. In this design, an attempt was made to create a heavy-duty version of the robot with minimal damage, which had a slightly larger diameter than the previous version. The design of the cable collector and the control console in two formats that can be installed on a van and installed on a van or portable were new features of the design of this model, which offers a more economical option to the customer. Reducing the diameter of the head to … is another feature of this model.

SewBot VII

This version, also known as the Model 6+, was designed and built with minor modifications from the Model 6 version.

SewBot VIII

Model 8 of this family was accompanied by a redesign of the body and a reduction in length and diameter…, the robot board was also redesigned and some past challenges were resolved, the head was also designed with a shorter length… and reliable operation capability to reduce the length of the robot, the addition of a lift, which was removed in model 6 and 7, designed according to the needs of the country’s water and wastewater industry, was designed and manufactured with a new mechanism…. Redesign of the electrical panel and miniaturization of the cable collector for deployment in the small Inroads van are other features of this model.

SewBot VIIII

Model 9 of this family was designed with smaller dimensions specifically for inspecting sewer lines with a diameter of 150. It has a lightweight aluminum body, reduced body diameter and head diameter, and due to these dimensions, the price is more economical than other features of this model.

SewBot X

Version 10 of this family has been designed and built with a mature version approach capable of competing with international and export models by adding turning power, reliable lifting, a significant reduction in the length of the body and head, and also, for the first time in this family, adding 2 wheels and making it 6 wheels, while maintaining all the positive features of version 8 of the robot.