Sewer network inspection services

Among the various types of activities in the industrial field, inspection has a special place in the industry. The inspection process includes checking and ensuring the quality of manufactured products, as well as awareness of damages to industrial facilities during operation and prevention of crises in other industrial processes.

Facility inspection or in-service inspection or, better said, operational inspection is a tool for collecting data related to the status of industrial facilities in order to prevent crises or heavy overhaul costs by knowing them with the help of an appropriate preventive maintenance program (PM). Inspection in industrial facilities has various types, from destructive inspections and tests to non-destructive tests and inspections.

In non-destructive inspections (NDT), which do not damage or harm the inspected facility, there are various types, including visual inspection (VT), liquid penetrant testing (LT), magnetic particle testing (MT), radiographic testing (RT), ultrasonic testing (UT), and phased array ultrasonic testing (PA), etc.

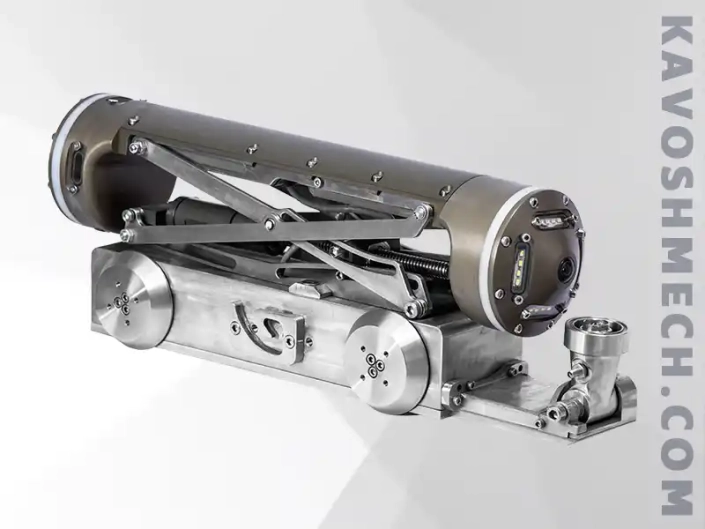

In the water and wastewater industry, inspection is non-destructive and visual, which is why it is sometimes called Videometry. Videometry is the measurement and visual inspection (along with recording images and video) and the collection of other information about the dimensions, size and quality of defects and damages by recording their location.

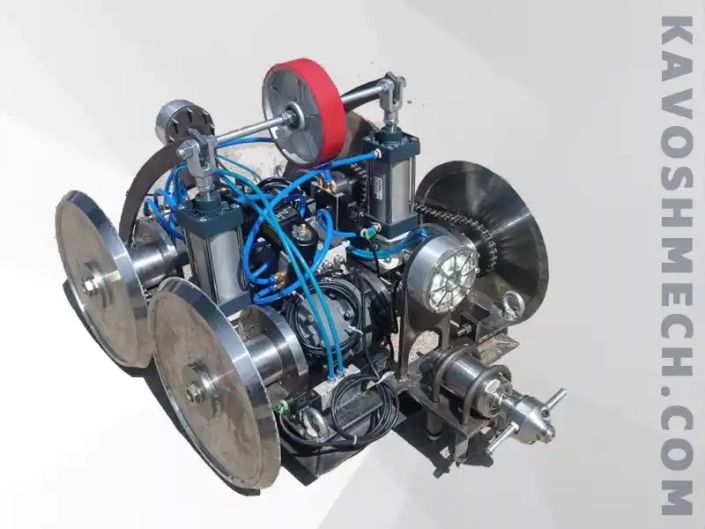

In general, with the advancement of science and industrial achievements and the need for greater accuracy in the production of products and the quality of services on the one hand, and the improvement of human safety standards on the other, the need to use robots has become more and more felt in the industry. In other words, in situations where either inspection by humans is not possible due to access restrictions, small dimensions, lack of sufficient light, etc., or due to the presence of hazards such as toxic and explosive gases, it is not safe for human work, the robot replaces the human to complete the inspection operation robotically.

When performing robotic videometry operations, by using various sensors, other parameters such as temperature, pressure, slope, and double track width can be measured. Videometry in the water and wastewater sector is also performed with the help of other tools for various purposes. These tools include cable or spring inspection cameras (PushRod) as well as manhole inspection cameras, which are known as quick view and zoom cameras in the sewage sector, and videometry using deep well inspection cameras in the water sector.

ربات لایروبی و بازرسی مخازن نفتی

ربات لایروبی و بازرسی مخازن نفتی